1. Powder Coat Oven Overview and Components

A Powder Coat Oven cures powder-coated surfaces into durable finishes using controlled heat. Key components include insulated chambers (steel or ceramic), heating systems (electric, gas, or infrared), airflow fans, digital thermostats, and exhaust vents. Advanced 2025 models integrate IoT sensors for real-time humidity and temperature adjustments, ensuring uniform curing.

2. Applications of Powder Coat Ovens

Powder Coat Ovens are critical in automotive manufacturing (e.g., car frames), aerospace (aircraft parts), and furniture (metal cabinets). They also serve DIY enthusiasts for small projects like bicycle frames. Their ability to maintain temperatures between 300°F–450°F makes them ideal for heat-resistant plastics and metals.

3. Powder Coat Oven Price Range

Benchtop Powder Coat Ovens start at 2,500,whileindustrialconveyorsystemsrangefrom40,000 to $100,000. High-efficiency 2025 models with solar power compatibility cost 20% more upfront but reduce energy consumption by 35% over five years.

4. Proper Usage of Powder Coat Ovens

Preheat the Powder Coat Oven to the powder manufacturer’s recommended temperature. Place items evenly to avoid uneven heat distribution. Use a timer to prevent overcuring, which weakens adhesion. Allow components to cool slowly post-curing to enhance finish durability.

5. How to Choose a Powder Coat Oven

Evaluate workspace size, production volume, and material types. For automotive factories, opt for conveyor ovens with 500–1,000 lb/hour capacity. Small workshops benefit from compact infrared models. Prioritize ovens with UL/CE certifications and modular upgrade options.

6. Safety Tips for Powder Coat Ovens

Ensure proper ventilation to prevent toxic fume buildup. Install fire suppression systems and carbon monoxide detectors. Use heat-resistant gloves and avoid overcrowding the chamber. Regularly inspect electrical wiring and grounding systems.

7. Design and Efficiency of Modern Powder Coat Ovens

2025 models emphasize sustainability with ceramic insulation (30% heat retention improvement) and hybrid heating (infrared + convection). AI algorithms optimize curing cycles, reducing energy waste by 25%. Modular designs allow easy integration of UV-curing modules.

8. FAQs on Powder Coat Ovens

Q: What are common types of industrial powder coat ovens?

A: Conveyor, batch, and infrared ovens dominate sectors like automotive and aerospace.

Q: How often should Powder Coat Ovens be maintained?

A: Clean filters weekly, recalibrate sensors quarterly, and replace heating elements every 3–5 years.

Q: Can Powder Coat Ovens handle large metal components?

A: Yes, industrial models support parts up to 20 feet long, such as truck chassis.

Q: Are energy-efficient powder coat ovens cost-effective?

A: Solar-compatible 2025 models save $1,200+ annually in energy costs.

Q: What safety certifications should a powder coat oven have?

A: Look for UL 508A, CE, or ISO 9001 certifications for compliance.

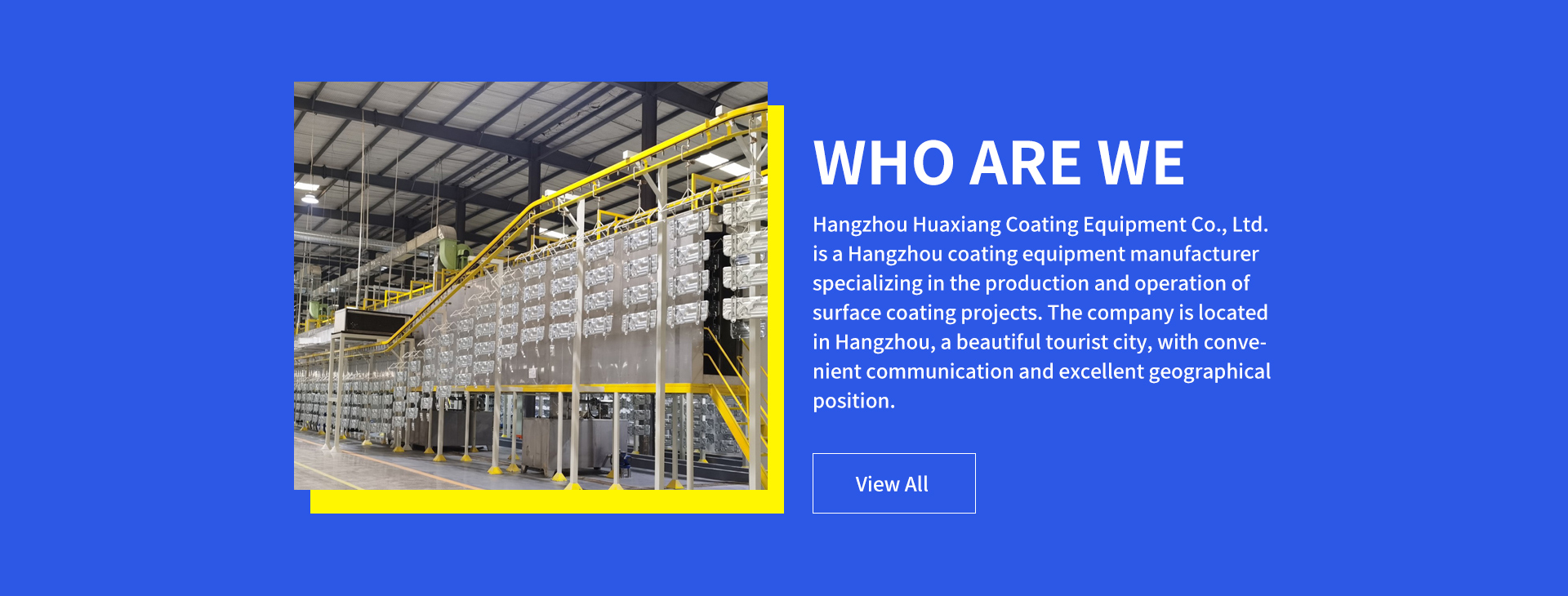

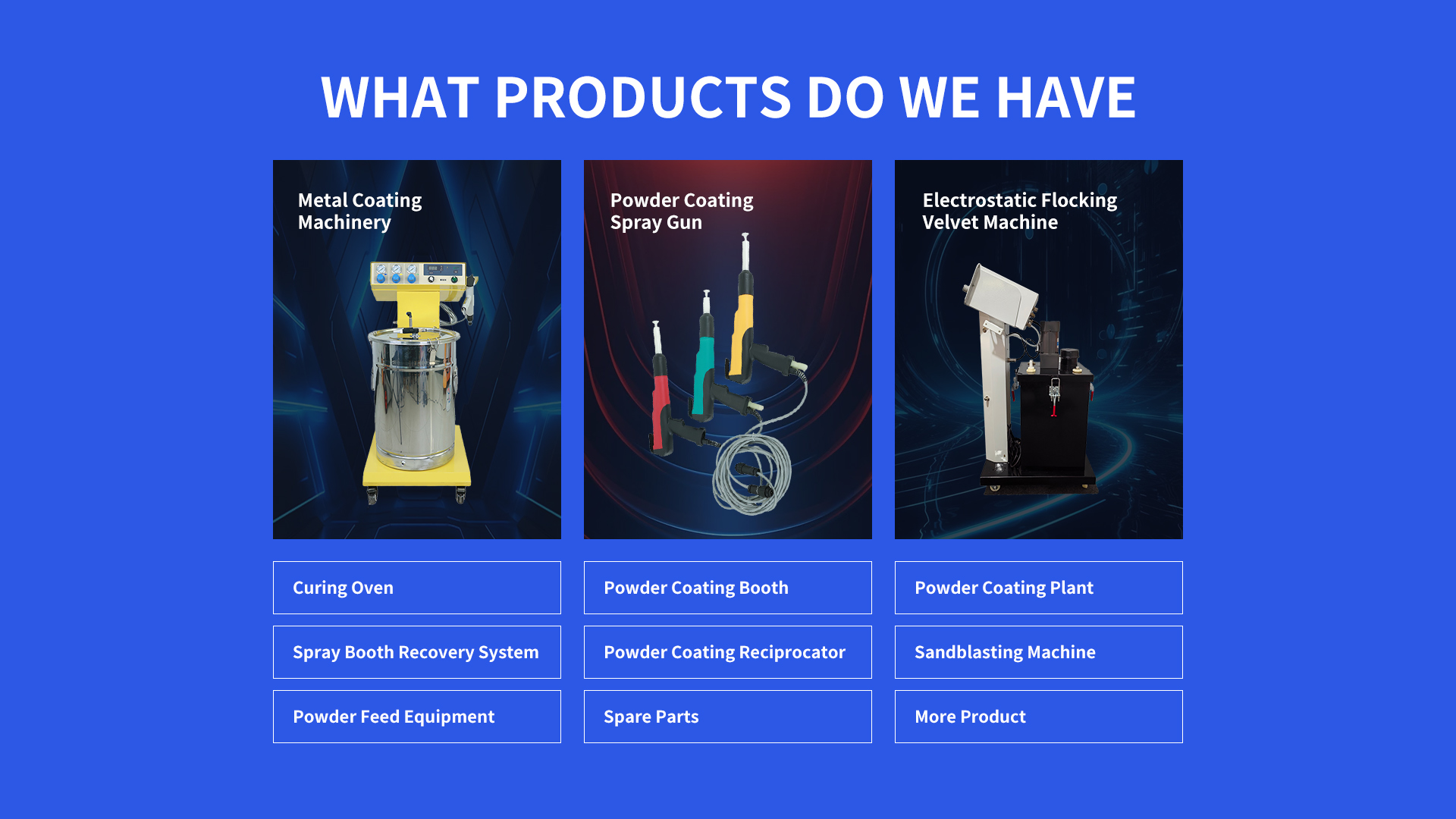

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com