In modern manufacturing, surface treatment technology is a crucial step in ensuring the durability and aesthetics of products. Powder coating, as an efficient and environmentally friendly surface treatment method, is widely used in the coating process of metal products. Among the various components of powder coating systems, powder coating ovens play a vital role. This article explores the functions, types, and industrial applications of

Powder coating ovens are one of the core components of a powder coating production line. Their primary function is to cure the powder coating applied to the surface of workpieces through high temperatures, causing the powder to melt and form a uniform, durable coating. This curing process not only enhances the adhesion of the coating but also improves its corrosion resistance, wear resistance, and aesthetic appeal.

Depending on production requirements, powder coating ovens can be categorized into several types, including convection ovens, infrared ovens, and combination ovens. Convection ovens use circulating hot air to evenly heat workpieces, making them suitable for parts of various shapes and sizes. Infrared ovens, on the other hand, utilize infrared radiation for rapid heating, making them ideal for thin-walled or small workpieces. Combination ovens integrate the advantages of both convection and infrared heating, offering solutions for more complex production needs.

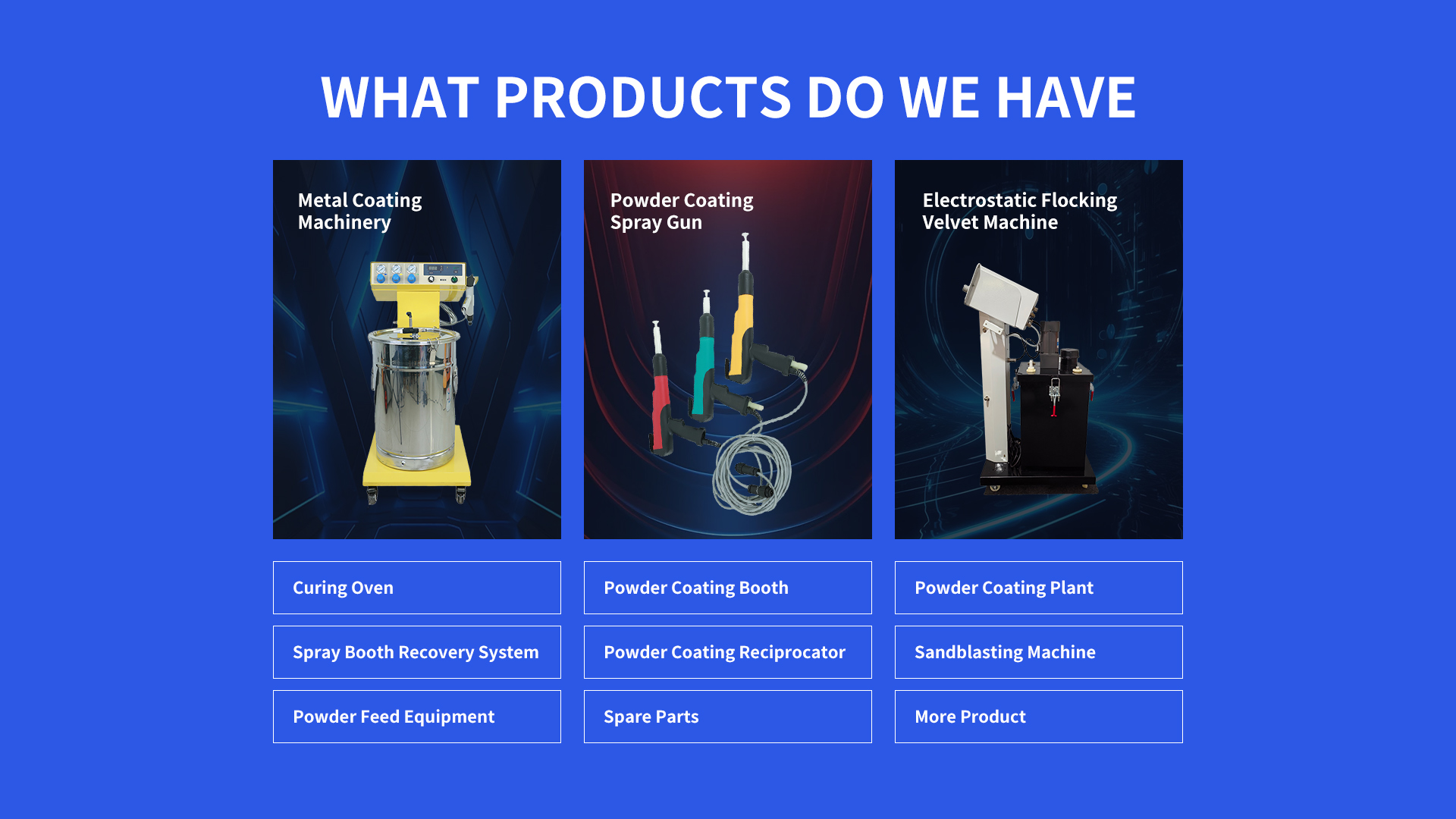

Advantages of Powder Coating Equipment

High Efficiency and Energy Savings: Modern powder coating equipment incorporates advanced heat recovery technology, significantly reducing energy consumption and improving energy efficiency.

Environmentally Friendly: The powder coating process does not emit harmful solvents, making it compliant with environmental regulations and reducing pollution.

High-Quality Coatings: Powder coating equipment ensures uniform coating thickness and excellent surface quality, enhancing both the appearance and performance of products.

Strong Adaptability: Whether for small components or large structural parts, powder coating equipment provides flexible solutions to meet the needs of various industries.

Applications of Powder Coating Equipment

Powder coating equipment is widely used in numerous industries, including automotive manufacturing, home appliance production, construction materials, and furniture manufacturing. In the automotive industry, powder coating is used for anti-corrosion and decorative purposes on car bodies and components. In the home appliance industry, it is applied to products such as refrigerators and washing machines for surface protection. In the construction materials sector, powder coating is used for surface treatment of metal products like doors, windows, and railings.

Conclusion

Powder coating equipment, particularly powder coating ovens, is an indispensable tool in modern manufacturing. It not only improves production efficiency and product quality but also aligns with environmental and energy-saving requirements. As technology continues to advance, powder coating equipment will continue to play a significant role in the surface treatment industry, driving manufacturing toward greater efficiency and sustainability.

By understanding the functions and advantages of powder coating equipment, businesses can better select systems that meet their production needs, thereby enhancing competitiveness and achieving sustainable development.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com